The work performed by motor torque sensors is a key element in the operation of machines. Torque: Torque is the force of rotation on a machine. The sensors correctly sense this force and send signals to the motor, so that the machine moves from there with a certain precision. Now, we will do a little deeper dive into the motor torque sensors and its application in different industries.

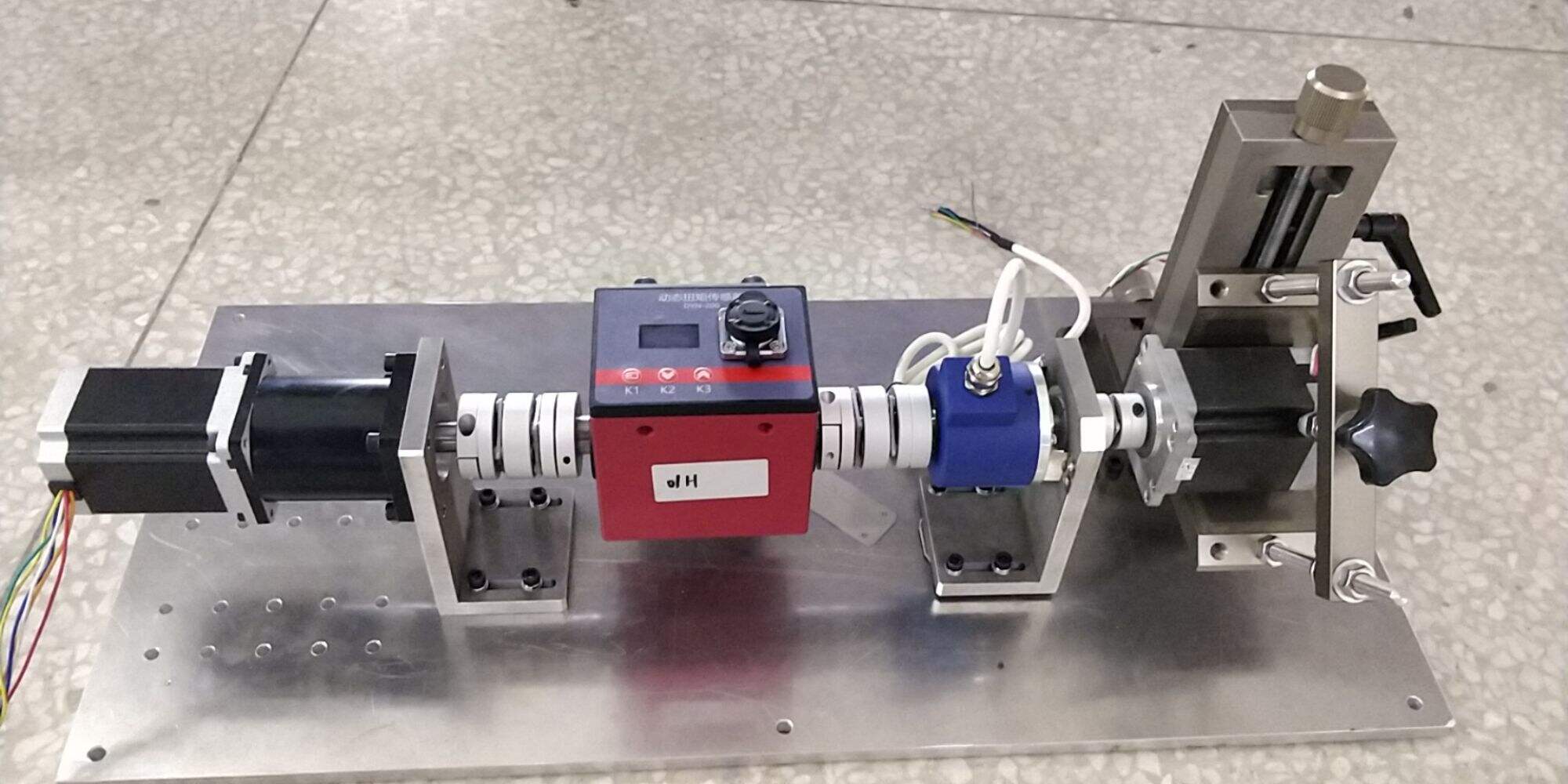

A strain gauge (central to any motor torque sensor) Strain gauges, are basically small parts that deform when stressed from the outside. This discrepancy was very carefully measured and translated into an electrical signal that can change the motor's settings for peak efficiency.

Applications of Motor Torque Sensors A lot of industries including automotive industry, robotics, etc seem to be utilizing these motor torque sensors. These sensors are used to maintain the power of engines in automotive applications, and optimize robot movements by incorporating them into robotics. Moreover, they have huge importance in the field of industrial automation.

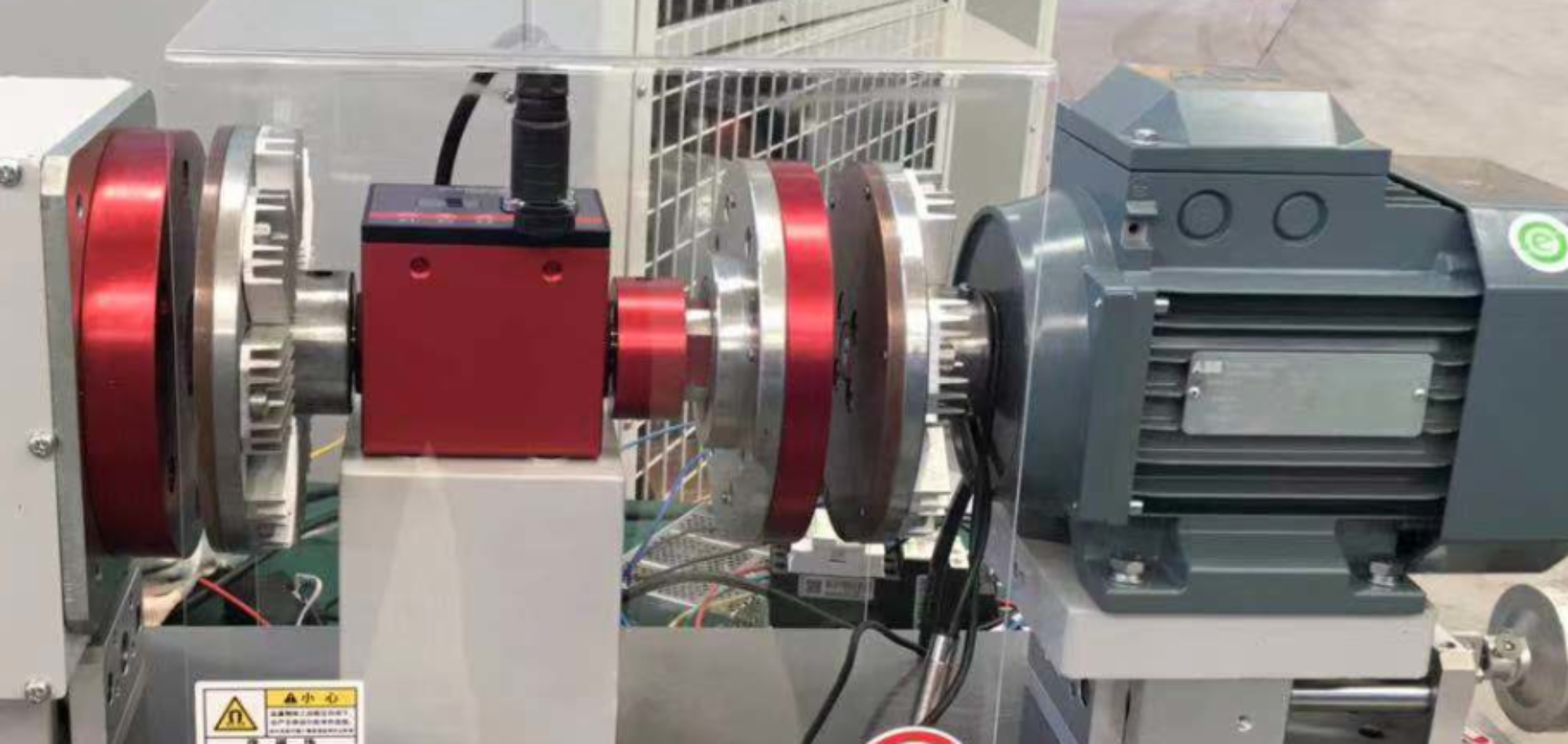

Motor control strategies are highly dependent on the high-quality data provided by motor torque sensors. This information can help in fine-tuning the speed and power output of a motor to achieve greater operational efficiency and save energy. In addition to that, these sensors also can detect the external attributes such as temperature variations or several vibrations and thus they lead to ceaseless machine operations.

Precision torque sensors - which are highly specialized (and much more expensive) than standard load cells, ensure that they provide the measurements of motor torques with very high accuracy. It is playing a vital role in improving the efficacy and power of machines by its ability to sense multiple microscopic differences in the twisting force.

The emergence of motor torque sensors is opening doors to a new age in industrial automation, providing improved precision and productivity for machine systems. They are mostly used to control machines such as conveyor belts, robots and assembly lines. They provide accurate motor torque data, and this makes them a great aide in making industrial machinery more efficient as well as reliable.

A point of interest for Organizations in Robotics and Motion Control Systems

They also play a crucial part for motion control systems, among which robots undoubtedly benefit as they enable the meticulous control of all movements made by those machines. These sensors enable robots to move accurately and with control, resulting in similar levels of precision when performing tasks in the manufacturing sector. High-speed and high-power outputs are controlled by the motor torque sensors governing the binary speed responses to ensure flawless machine operations, such as in CNC machines or 3D printers.

As such, motor torque sensors play an integral set-up for a wide range of industries contributing to the overall performance and efficiency in various applications. This is a key reason why they are such prominent and critical elements in modern motion control solutions that have disruptively transformed automation across industries, from the driving experience of automobiles to the very architecture of aircraft wings, down to life-saving instruments used in medical equipment: STMicroelectronics.

Customers can select from range of transportation services. We provide secure packaging speedy delivery all stock goods. Tracking information be motor torque sensor after goods are shipped.

Our main products are comprised of different types of sensors, such as linear displacement sensor draw wire sensor LVDT sensor, load cell torque sensor, magneto sensor, pressure sensor more. We are able provide OEM/ODM service motor torque sensor customer requirements

Our company certified by CE, RoHS, ISO9001 and various certifications. Prior to shipping, check every product. Additionally, SOP professional engineers provide after sales service to resolve product use and other motor torque sensor.

SOP is a manufacturer high-tech motor torque sensor that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.