Applications of Reaction Torque Sensors in Engineering

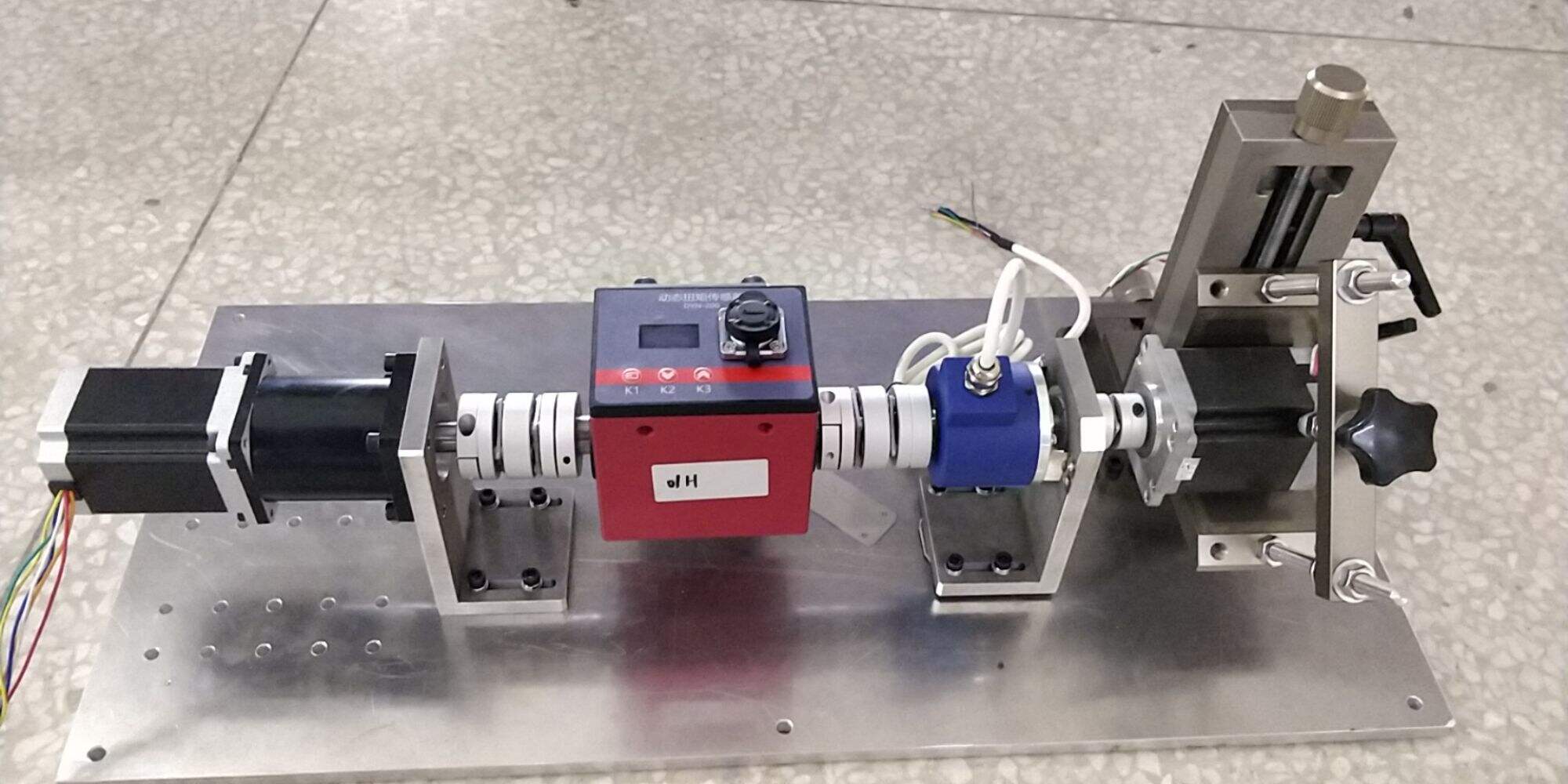

This article will discuss the importance of precision control in one simple area of this huge world that is engineering. In this context, torque is a measure of how much the shaft you are spinning twists when force is applied to it. It is this kind of precision that matters in many applications - determining the torque within a car engine or monitoring forces along an assembly line, for example, or even sensing and reacting to movement from computer-controlled robotic arms. Sitting at the heart of this precision are some unsung heroes, called reaction torque sensors.

Torque sensors are high precision transducers that operate in a critical location of the engineering spectrum, supplying invaluable insight to enhance functionality and safety while driving systems. This article furthermore examines how reaction torque sensors are evolving across various industries and applications, demonstrating their significant role in the evolution of engineering.

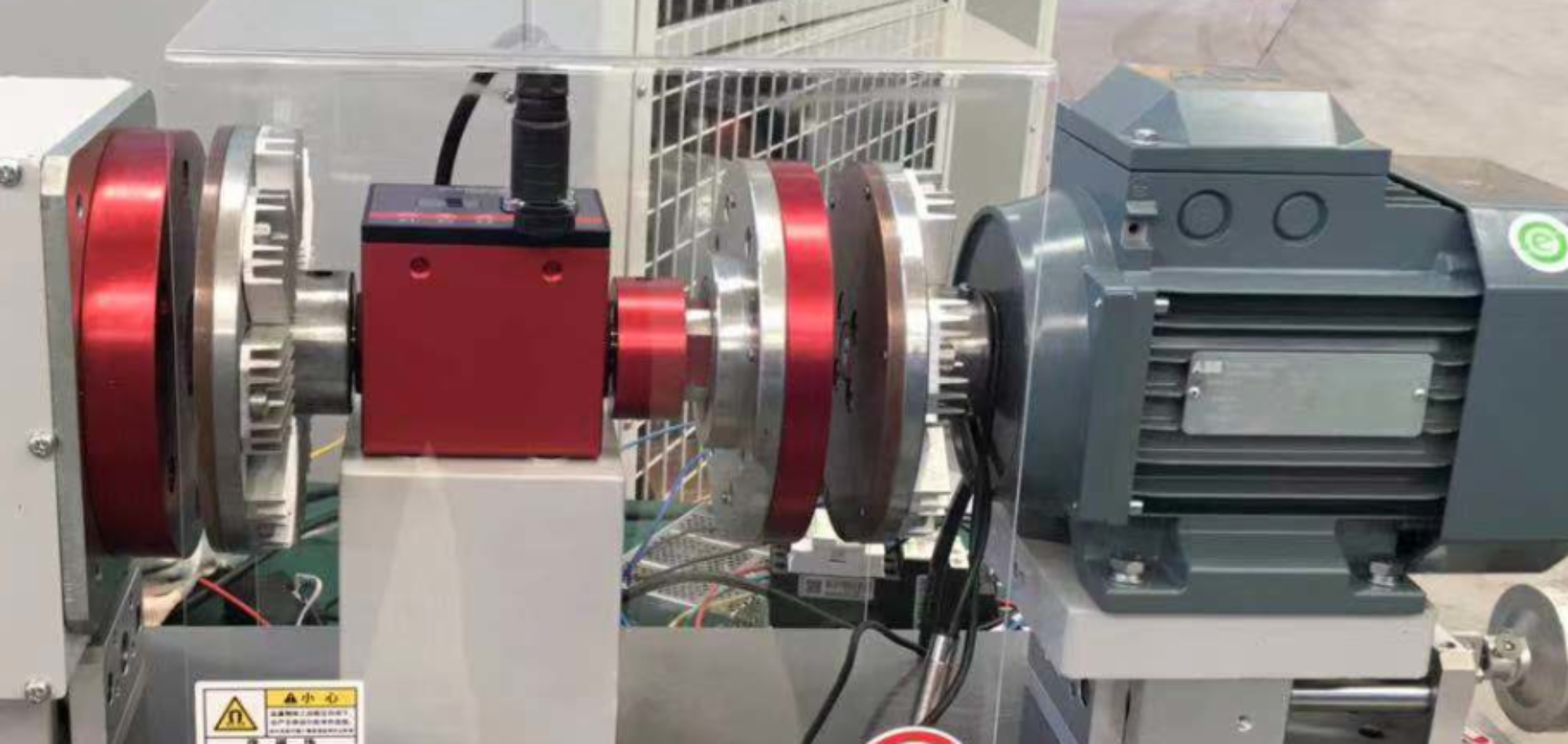

Torque is king in the automotive industry, making a reaction torque sensor one of the focal sensors at any up-to-date engine test department. Accurate engine power output measuring and detecting of malfunctions, monitoring the performance of assemblies such as transmissions and differentials all are reliant on these sensors. Reaction torque sensors combined with other sensors such as strain gauges, pressure and accelerometer give a 360degree view of engine operation leading to better designs reducing the overall space requirements /increasing efficiency.

Reaction torque sensors are widely used to control the level of torque applied in precision manufacturing. Such dedication to quality control guarantees that components meet their exacting standards and parameters, without blemishes or malfunctions. These sensors allow us to create effective, high-quality manufacturing processes with the help of tools such as process control, feedback and feedforward control. They are utilized in multiple areas such as aviation, electronics or medical devices and the automotive industry.

Reaction torque sensors witness a wide effect in the area of robotics. These sensors provide critical feedback to Robotic Systems which helps them alter the way they move as well provide improved performance. In addition, it is a cornerstone in dynamic force analysis (a procedure where forces and torques on the robot arm are measured real time). Real-time monitoring is critical here, and a stable platform must be guaranteed to avoid any unwanted vibrations or oscillations.

Optimising Wind Turbine Operations to Increase Efficiency

Reaction torque sensors are perfect for the wind turbine industry, which has intricate machines that need meticulous control and monitoring. These sensors measure the torque produced by wind turbines, which is important for ensuring maximum energy yield and safety. If torque is monitored it allows rides to detect potential failures early and benefit from an efficient use of energy. Operators of wind turbines that are trying to ensure peak operational efficiency also find this proactive approach invaluable.

Reaction torque sensors are crucial in the aerospace industry to ensure safety and reliability of aircraft. These type of sensors greatly help with torque measurements for different applications such as engine testing, landing gear validation and flight control systems. These sensors must be both extremely accurate and their accuracies matter greatly, as even small errors result in catastrophic outcomes. Reaction torque sensors in aerospace meet all the necessary requirements of extended and harsh operational conditions enveloping high temperatures, intense vibrations as well as extreme pressures.

Conclusion - The Growing Importance of Reaction Torque Sensors

Apparently, in the contemporary engineering domain we are more towards employing reaction torque sensors due to their supreme accuracy and utility it offers which still remains irreplaceable. The use of these sensors is not just as common in most industries but also a critical part for the more stringent control. From car engine performance, industrial manufacturing, robotics accuracy to wind turbine monitoring systems and aircraft security - it is reaction torque sensors leading the path toward precision engineering. They are due to become more and more vital as technology continues its relentless advance, which could see them playing a key role on future engineering advances.

Our main products are comprised different types of sensors, such reaction torque sensor displacement sensor drawing wire sensor LVDT sensor, load cell torsion sensor, magneto sensor, pressure sensor, etc. We provide OEM/ODM services depending on the need's client.

We offer safe and secure packaging every item expedited shipping, with 2 days delivery for stock reaction torque sensor There several kinds shipping services for customer to select. Following the delivery you will be provided with the tracking information.

Our company been reaction torque sensor by CE, RoHS, ISO9001 as well other certifications. Before shipping, we inspect each product. SOP also engineers can provide after-sales service solve any issues with the product.

SOP is a manufacturer high-tech reaction torque sensor that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.