A static torque sensor measures the amount of twist in a bolt or nut, and is essentially another tool that mechanics across all industries use. We also refer to this twisting force as torque. This is crucial in industries that involve creating things (Manufacturing) and Industries where people build stuff,it tells how strong we are turning something.

Key considerations when selecting a static torque sensor Firstly, it must be able to measure torque accurately. You should also check whether that sensor is able to measure the amount of torque needed for your application. These points will help you to select the right sensor for yourself.

Industrial Use of Static Torque Sensors A key benefit of them is that they work in small spaces, which can make them versatile tools for different workspaces. In addition, these sensors are user-friendly and do not require extensive training to operate them. As they are capable of delivering accurate results their use is essential in ensuring health and safety, as well as numerous quality standards that need to be maintained within the workplace.

Static torque sensors, like any other instrumentation for measurement and testing purposes need to be regularly calibrated or maintained in order to keep their performance at the highest level. Calibrating the sensor is needed in order to insure correct torque measurement, and that crucial reliability of results. Additional recommended practices such as periodic maintenance (keeping foreign materials off the sensor), are also important to a sensors lifespan and performance. This is very important in the overall performance and effectiveness of your sensor also helping to store it correctly when not being used.

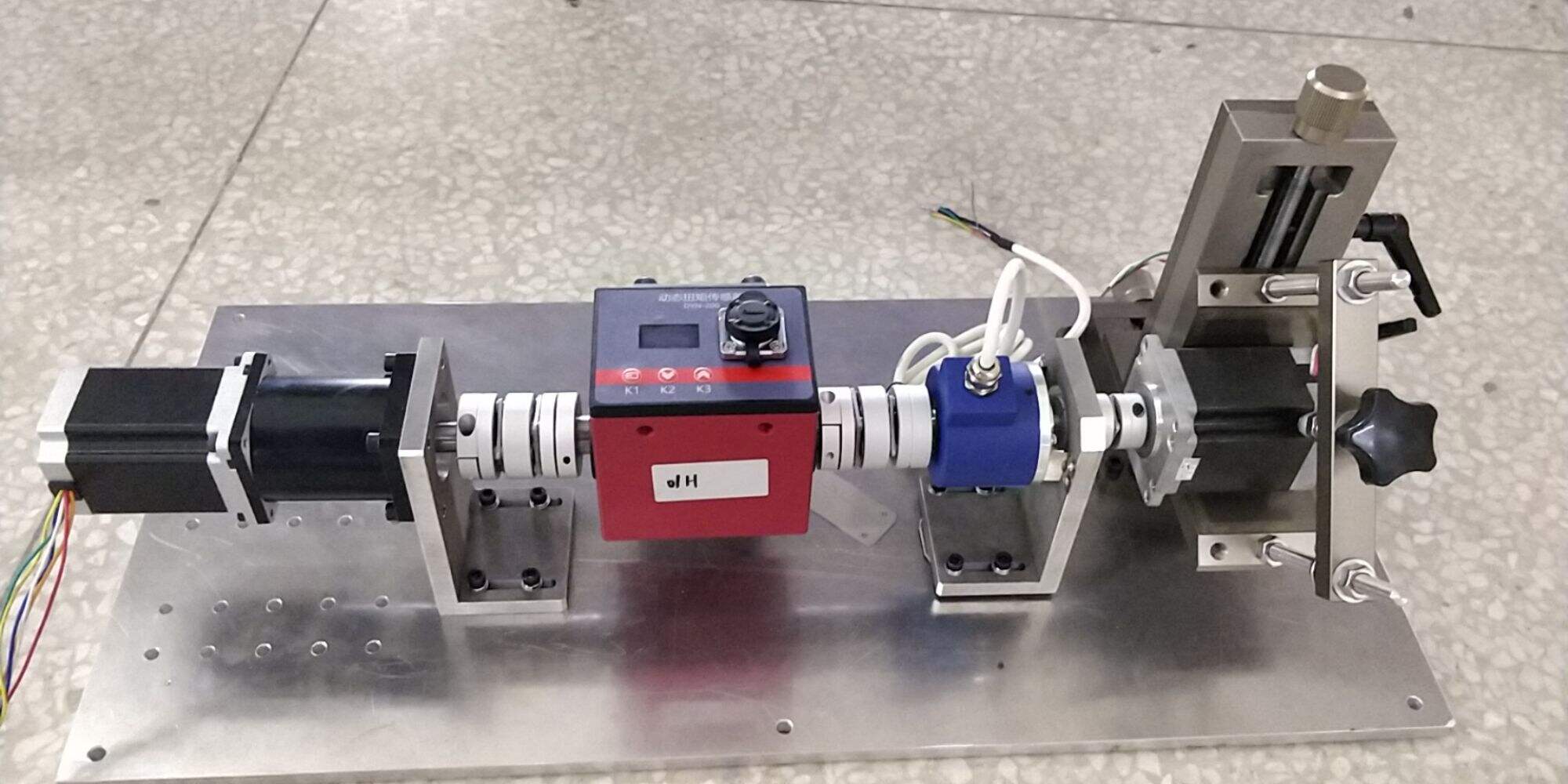

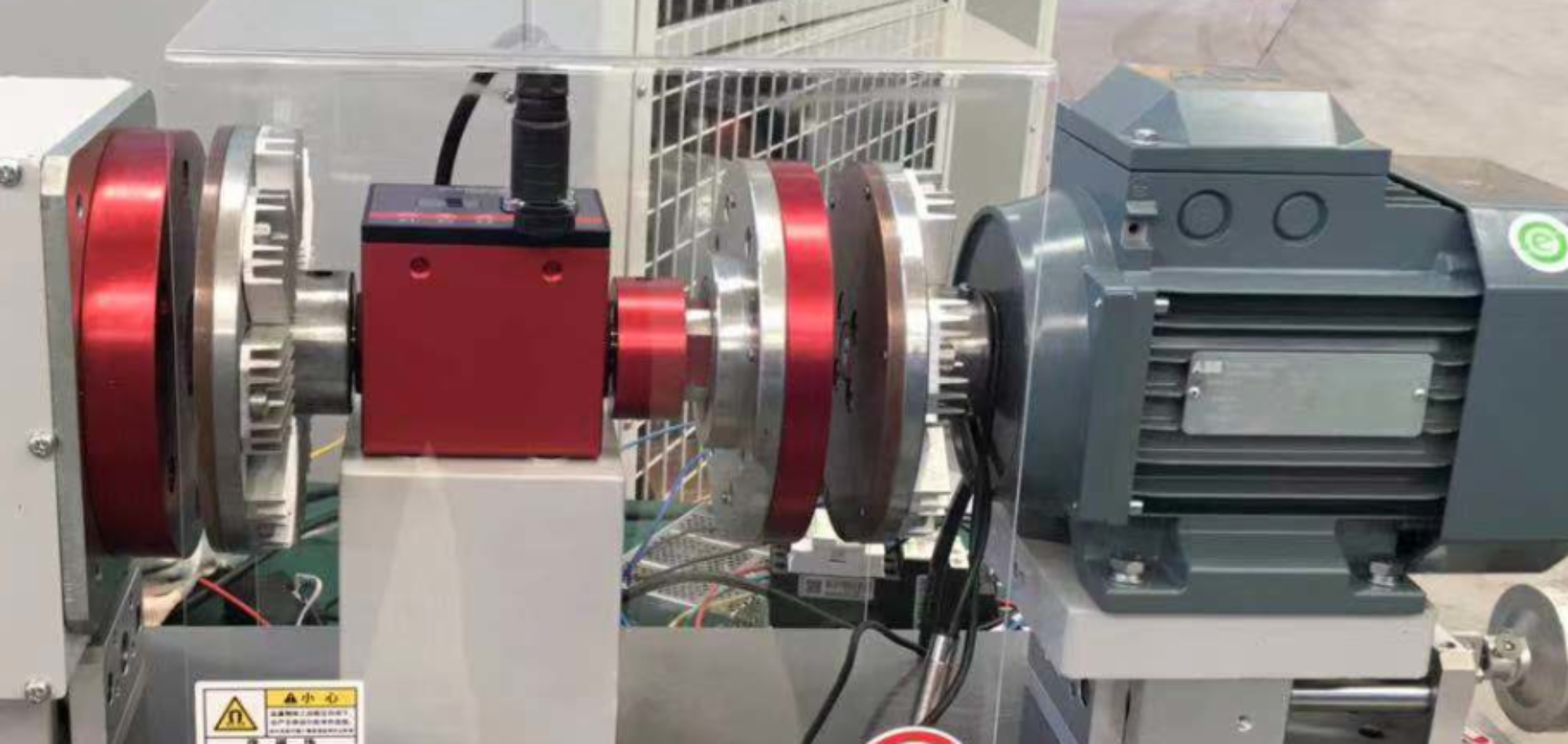

As there are different types of static torque sensors that vary in features and capabilities. The reaction torque sensor, for example, measures torque by reacting against a rigid surface; obviously this method of measurement is quite specific. A shaft torque sensor records how a shaft twists, thus measuring the level of Torque in another way. Such digital torque sensors swot the figures on a screen making it easy to for you be cognizant of how much force is required while obtaining velocity data.

To sum it all up, static torque sensors are a vital instrument to determine the amount of twist that a bolt or nut is subjected to. When you are choosing a static torque sensor, it is crucial to find out if this error can have an impact on the measurement results of your device and which range measures the devices with such errors support. These Sensors Are Very Useful In Industrial Applications Because Of Their Efficiency, Accuracy And User-Friendly Nature. It is necessary to have occasional calibration and maintenance procedures in order for it work competently. This means that there is an appropriate solution for every application or requirement with the different static torque sensor offerings as all of them have their specific features.

We provide a broad range of products include linear displacement sensors drawn wire sensors, LVDT sensors, load cells torque sensors, pressure sensors, static torque sensor sensors, more. We offer OEM/ODM support per the specifications of the customer.

Customers can choose from a variety transport services. We provide secure packaging and quick shipping all stock goods. The static torque sensor information be sent to you following delivery your goods.

We are certified CE, RoHS ISO9001. Our products undergo rigorous static torque sensor prior delivery. SOP also has engineers who provide after-sales service and solve any issues the product.

SOP is a high-tech manufacturer has over 20 years of static torque sensor production and worked with more than 5000 customers around world. It is a well-established company engaged research, development and production of different types of sensors.