Having the right tools is crucial when we want machines to work well. Linear position sensors ensure that machines are working properly. With so many, how can you choose the best for your needs?

One thing to consider is how powerful the sensor is. Robust Sensors

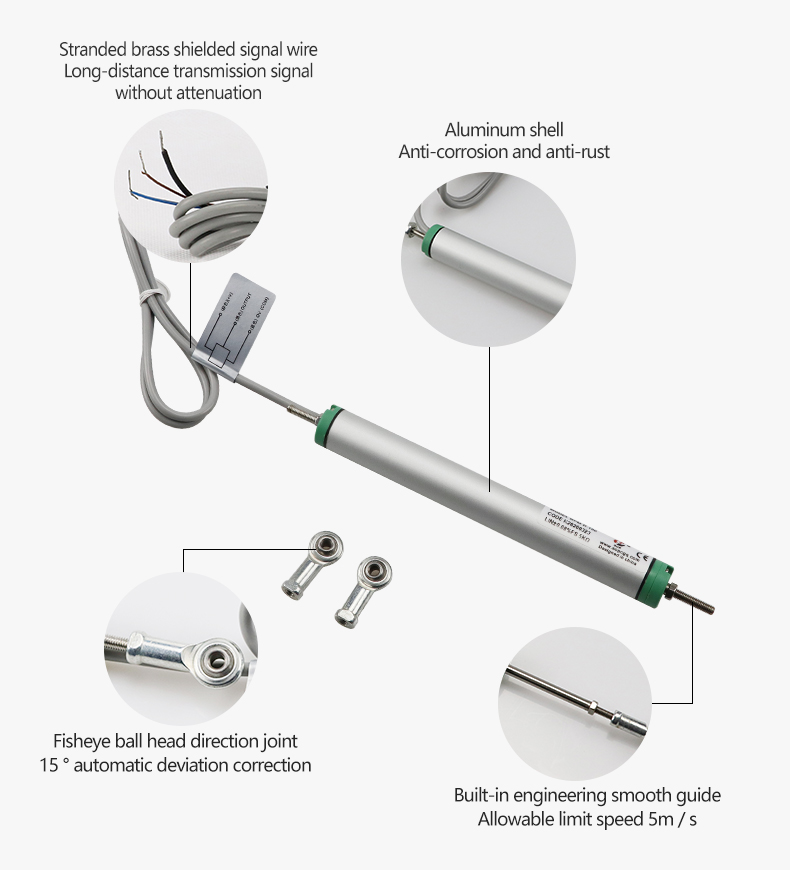

Robust sensors are not designed to break. Over time, this may end up saving you some cash since they won't have to be repaired or replaced frequently. Be sure to pick a linear position sensor that is well construct from quality materials and designed for reliable operation. This helps maintain your machines in good order for years to come.

Advanced Sensor Technology for Implementing Preventative Maintenance Strategies

Regular preventive maintenance is a vital way to keep machines in tip-top shape. Preventing expensive breakdowns and extending the lifespan of your machines is possible through routine checks and replacement of worn-out parts. Preventative maintenance is aided by linear position sensor as they provide up-to-the-second details of exactly where moving parts are located. This can help you identify issues before they become larger problems, allowing you to address them sooner.

Best of all, advanced sensor technology enhances preventative maintenance with increased accuracy and insights. Ensure that problems never catch you off guard and you can maintain your machines in good operating order. However, buying good sensors that are high-tech will save you time and cost for repairs in the long road.

High-Quality Position Sensors to Maximize Efficiency and Minimize Downtime

Linear position — magnetostrictive linear position sensor aid in improving the efficiency of moving sensors by giving accurate data. It gives workers the information they need to make adjustments when necessary to keep the machines operating at peak levels.

To achieve efficient operation and minimize downtime, high-quality position sensors are essential. They withstand heavy use and deliver accurate data in the most challenging environments. You want to choose some solid sensors so you can reduce the likelihood of random failures and keep everything going as planned.

Linear Position Sensors – Robust Position Sensors To Ensure Long Lifespan Of Equipment

To maximize the usefulness of your machines, you should be trying to extend their lifespan. This is made easier with the use of linear position sensors that provide essential information about the positions and movements of various machine parts. You can also monitor this information for signs of wear and tear, and address them before they become major problems.

These linear position sensors are built for durability, making them perfect for taking into account the increased service life of machinery seen across industrial applications. Good use of sensors from the get-go can help keep your machines operational for decades, which could help you save time and money on repairs down the line.

Invest in Reliable Sensor Solutions to Save Time & Money

Ultimately, investing in trusted sensor solutions offers the best solution to reduce maintenance costs. Choosing the right linear position sensor, implementing preventative and predictive maintenance, optimizing efficiency, prolonging the service life of your machines and minimizing downtime will help you save time and money in the long run. SOP provides several top-tier, robust linear position sensor potentiometer to help you keep everything on track. With the SOP sensors, you can keep your machines running right and true for decades to come.

Table of Contents

- One thing to consider is how powerful the sensor is. Robust Sensors

- Advanced Sensor Technology for Implementing Preventative Maintenance Strategies

- High-Quality Position Sensors to Maximize Efficiency and Minimize Downtime

- Linear Position Sensors – Robust Position Sensors To Ensure Long Lifespan Of Equipment

- Invest in Reliable Sensor Solutions to Save Time & Money

EN

EN

AR

AR HR

HR CS

CS DA

DA FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF KA

KA UR

UR BN

BN