Learn About The Great Benefits Of A Rotary Torque Sensor

Counterintuitively, the ability to measure how well (or poorly) these contraptions are doing is a precious instrument in designing and evaluating various kinds of devices. What Can It Do The BestExamples:Rotary Torque Sensor In this article, we have discussed the advantages of using a UK SensorTech rotary torque sensor along with some additional key points.

A Rotary Torque Sensor for Your Needs

Measurement of so much important factor to a lot of production methods, torque measurement is also subjected during the scope for operations security and productiveness in addition to efficiency. Some of the advantages you can get from this Rotary Torque Sensor are:-

High Accuracy - A respected producer of rotary torque sensors will produce devices that can accurately measure forces at numerous locations within machines. With these sensors, deviation in torque to the minutest value can be detected and logged aiding for high precision manufacturing process.

Enhanced Manufacturing Efficiency - Rotary torque transducers provide fast and precise tests of the level of torques to enhance production difficulties. This in-turn ultimately results in better process control resulting into less cycle times which turn out to be cost savings.

Business Economic - Even highly professional grade rotary torque sensors are also very economical and they will show their worth in huge number of scenarios as Industrial Torque Sensor. This makes them a great contribution for any business wanting to improve production accuracy and also reduce costs at the same time.

FIELD SUITABLE - Their generalist approach makes rotary torque sensors second to none in that they can be used across different fields like motor testing, automotive testing automation as well aerospace & aviation and other R&D environments.

The Benefits of Mode Innovations and Safety Were Emphasized

As such - a good manufacturer of the rotary torque sensors is going to focus on new, safe design features for their range. These sensors are constructed with several semiconductor technology manufacturing innovations and use of smart materials for safe use. They must be kept in a loop for continuous innovation and improvement of their products which means, the customer is always this passive input into suppliers offerings.

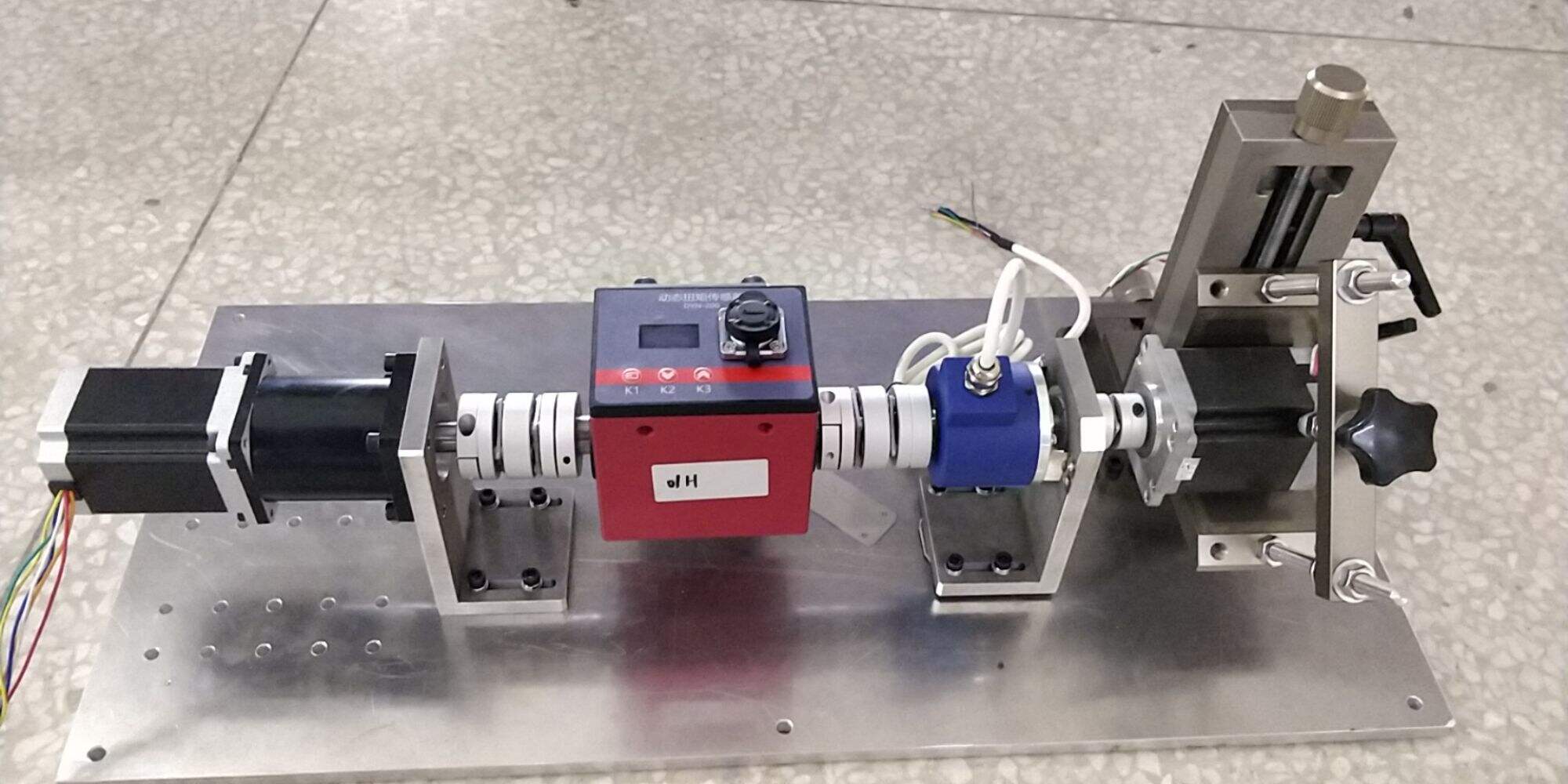

Step by Step Guide To Use A Rotary Torque Sensor

Anyone who is not a complete expert in this area should be able to make use of rotary torque sensor without any need for effort. First you need to install the sensor and then., pinch it on your shaft_HELP [ISTOCK:OMNISCIENCE] With again proper installation positioning directly inside of a machinery, you can assuredly read torque data correctly.

Quality of services and products

The esteemed manufactures take care that their basket of services are more than just manufacturing and supplying, meticulously put in place to earn the best possible level customer satisfaction when you buy a rotary torque sensor from them.(firesal716_die) A good supplier will provide customer service and offer you a choice of your sensors that can be sent in for installation assistance as well as mechanical maintenance support. Besides, that they have to be accredited in the business on some planes.

Applications of Rotary Torque Sensors:

A rotary torque sensor is an essential tool for measuring the power output of engines, such as in the automotive industry and many other industries. They are also used as a non-rotating means to measure torque on propellers and turbines of aircraft engine. If the industrial automation environment, without such sensors cannot be controlled accurately distributed torque visitors motorized machines.

Hence, having a quality carbon rotary torque sensor supplied by an established UK based all major industries need become very important. The NETZSCH M.O.V.E pumps are designed for use with a selection of compatible NETZSCH sensor models providing the calibration and verification in to-date measurement of these critical parameters in order that higher accuracy measurements may be guaranteed during production processes as well safe operations. Make sure you select the type of services delivered as well product quality & adaptation, before making plan purchase a rotary torque sensor.

EN

EN

AR

AR HR

HR CS

CS DA

DA FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF KA

KA UR

UR BN

BN