These units are known as compression force sensors, and we use them to measure how much strain a substance is putting on the system. They work as a weight detector, and this is important because the more pressure something can handle without cracking or going bad. The 圧縮ロードセル by SOP are composed of special materials that change their properties whenever they get pressed or compressed. This lets us read a quantifiable value of the sensor and tells how much force is being used.

Uses of Compression force sensors are quite a lot in different types of work and sectors. They are, for example important in the production of cars, airplanes and other items etc. These sensors are used by engineers and workers to know if it can sustain their activities given the magnitude of force they apply into them. These sensors are designed in various forms - from tiny ones that can insert into toys to big sizes where they capture heavy machinery. It is used to measure weights of various types, from lighter loads such as a few grams up to much heavier weights. This 圧縮荷重 from SOP versatility makes them highly useful for many of businesses use cases.

これらの SOP 圧縮力センサーを使用すると、科学者やエンジニアは、さまざまな材料を組み合わせて使用することで、これまでにない方法でそれらの力を測定できます。より正確な測定により、これらの専門家はより優れた、より長持ちする製品を構築し、顧客の安全を確保できます。このようにして、企業はセンサーを使用して、自社製品が厳格なセキュリティおよびパフォーマンス基準に準拠していることを確認できます。このようにして、事故を防ぎ、私たち全員にとってより安全な製品が作られます。

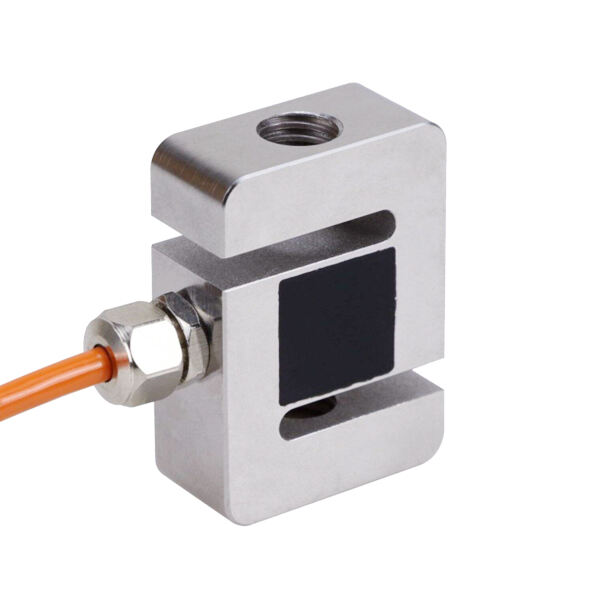

Compression force sensors are available in many different styles these days. Load cells, piezoelectric sensors and strain gauges are some of the most common types. Load cells are sensors used to detect how much force, or weight in this case is being applied to them by measuring the deformation of a material. Piezoelectric sensors happen due to special material inside these which upon compression generates electrical charge. Strain gauges are positioned to measure the strain on an object (load forces) indirectly; as stress is beginning to build-up more than material can handle, materials bending or deforming changes. These 張力および圧縮ロードセル センサーの種類にはそれぞれ利点と欠点があるため、特定のタイプの選択は特定の使用事例の要件に応じて異なります。

Why You Should Use Compression Force Sensors? Arguably their most significant contribution is to enhance accuracy in testing and quality checking. Compression of a material can result in certain changes that give crucial strength information about it. These sensors also allow manufacturers to minimize the need for physical testing during production. Acceleration in production, not only Saves monetarily Businesses need better products that are more innovative and reliable, using compression force sensors will enable this which itself translates into higher customer satisfaction. These sensors are also important industry all over the world that overall help in making more reliable and efficient.

We provide secure reliable Compression force sensor each product, and speedy shipping 2 days for stock goods There numerous types of transportation options available customer to choose. Following the delivery you will be provided with tracker details.

SOP is a manufacturer high-tech Compression force sensor that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.

Our company certified by CE, RoHS, ISO9001 as well other certifications. Our products undergo rigorous testing prior delivery. SOP also offers engineers offer after-sales services Compression force sensor any product issues.

We provide a broad range products, including linear Compression force sensor sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.