In the realm of structural engineering, few concepts carry as much significance as compression load. This fundamental force, exerted vertically or horizontally on a structure, is a pivotal consideration in ensuring stability, durability, and safety, as well as the SOP's sensor pressure transducer. As modern construction pushes the boundaries of design and material capabilities, understanding and managing compression loads have become increasingly vital.

At the heart of contemporary architectural marvels lies a meticulous comprehension of compression loads, also the load cell 50kg from SOP. These loads, which push elements together, are crucial for maintaining structural integrity against gravity, wind forces, and even earthquakes. In skyscrapers that pierce the sky and bridges that span vast distances, precise calculation of compression loads ensures that each component can withstand these pressures without buckling or collapsing. By integrating an in-depth analysis of compression loads into the design phase, engineers can create structures that are not only visually stunning but also resilient over time.

Efficient management of compression loads goes beyond safety; it is also a strategic tool for cost optimization, just like the SOP's product called rotary torque sensor. Through advanced computational models, engineers can simulate various load scenarios to identify areas of stress concentration. This analysis enables the redesign of elements to minimize excess material usage, thereby reducing construction costs without compromising on strength. Moreover, understanding the precise compression load requirements allows for the selection of optimal materials, further contributing to cost-effectiveness and sustainability in construction projects.

Compression load management finds application across a myriad of real-world scenarios, identical to load cell and amplifier developed by SOP. In bridge construction, it plays a pivotal role in designing piers and abutments capable of withstanding the immense weight of traffic and environmental forces. Similarly, in high-rise buildings, managing compression loads is essential for designing robust foundations and column systems that distribute loads safely to the ground. Even in renewable energy infrastructure, such as wind turbine towers, managing compression loads is crucial to ensure stability against strong gusts and vibrations.

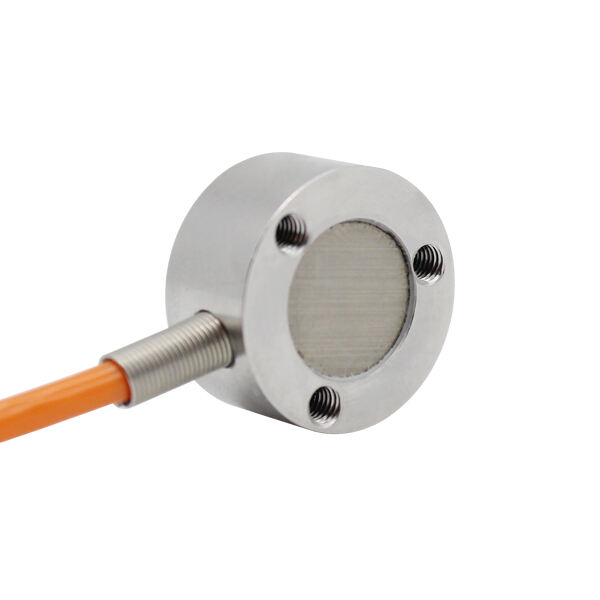

Structural failures, often catastrophic, underscore the importance of accurately assessing compression loads, similar to the SOP's product like compression load cell. The collapse of the Morandi Bridge in Genoa, Italy, serves as a stark reminder of what can happen when compression loads are misunderstood or underestimated. Comprehensive analysis helps predict potential points of failure, allowing for preventive measures such as reinforcement or redesign. By incorporating a thorough understanding of compression loads into the design process, engineers can significantly reduce the likelihood of such disasters, safeguarding human lives and property.

SOP is a manufacturer high-tech Compression load that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.

Customers can select from range of transportation services. We provide secure packaging speedy delivery all stock goods. Tracking information be Compression load after goods are shipped.

We provide a variety products including linear displacement sensors drawing wire sensors LVDT sensors, load cells torque sensors pressure sensors, magneto sensors, many more. We are able provide OEM/ODM service as per the Compression load of customer.

We are accredited CE, RoHS and ISO9001. We make that each product undergoes rigorous inspection prior shipping. Additionally, SOP has professional Compression load after-sales assistance for product problems, as well as other problems.

The advent of sophisticated technologies has transformed how compression loads are analyzed and estimated. Non-destructive testing methods, such as ultrasonic testing and ground-penetrating radar, provide real-time insights into material properties and hidden defects, enhancing load estimation accuracy. Additionally, machine learning algorithms are being employed to analyze vast datasets, identifying complex load patterns and predicting load behavior with unparalleled precision. These advancements, coupled with cloud computing and simulation software, empower engineers to simulate countless load scenarios swiftly, enabling more informed decision-making and pushing the boundaries of structural design.

In conclusion, compression load stands as a cornerstone of modern construction, influencing everything from initial design to long-term structural health, same with the compression load cell supplied by SOP. Its careful management optimizes costs, prevents failures, and underpins the creation of innovative structures that define our skylines. As technology continues to evolve, so too will our ability to understand and harness the power of compression loads, ensuring a safer and more sustainable built environment for generations to come.