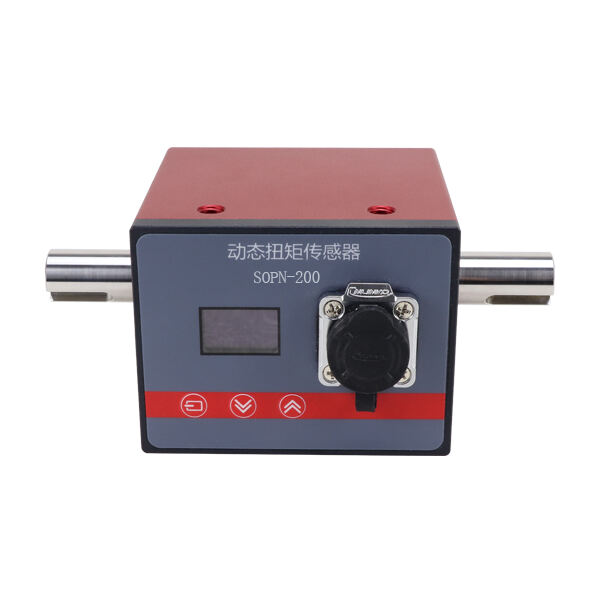

Whether these are in the very first stages of entering or at already part-way up business ladder, all companies need to find ways into which they can work more efficiently and cut costs. SOP rotary torque sensor. It is a great way to do this.

Considering the fact that these are there technologies how does sensor torque technology work. This method started with measuring wheel and drum rotation speed. This is useful for businesses to see how good their machines are and to catch issues early. Locating issues at an early stage saves time and money, ensuring a more streamlined procedure.

There are some nifty ways in which businesses can be more efficient nowadays all thanks to new sensor tech. Here is the example using wireless torque sensors. These SOP load sensor help you to see how efficiently your devices are performing somewhere far. Perfect for hard to reach and unsafe areas.

Another way is use multi-axis torque sensors. These sensors measure the amount of force a machine is exerting in different directions, ideal for more nuanced work. Another style is a smart torque sensor that collects data to reveal how the machine is performing and when it needs servicing.

Precise sensor torque solutions are crucial for businesses relying on engines (such as car or airplane makers). These SOP pressure sensor 4 20ma tools provide real-time tightening data and can detect even very small faults, so you can react early. It helps you prevent major repairs and maintain the quality of your products.

This helps businesses in doing better work while keeping safe. When a part is being tightened very hard during assembly, business must use resistance data to confirm that these operations have been done right. Allows work to be done more efficiently and eliminates errors with SOP sensor load.

These systems can watch machines in real-time and notify people of any impending danger as well. Caution: if a device is extracting too forcefully it may be destroyed and dangerous. Identifying these problems early increases safety standards and decreases mishaps.

SOP has over 20 years production expertise collaborated over 500 global customers. It a professional manufacturing high-tech business that is engaged in the research, development manufacturing, sensor torque and service of various types of sensors.

Our company certified by CE, RoHS, ISO9001 and various certifications. Prior to shipping, check every product. Additionally, SOP professional engineers provide after sales service to resolve product use and other sensor torque.

We provide secure safe packaging every item and speedy sensor torque of 2 days delivery stock goods There are numerous types transportation options available customer to choose. The tracking information will be sent to you once the product is shipped.

We provide a broad range products, including linear sensor torque sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.