In industrial weighing, the load cell transmitter is one of the most important components which bridges the gap between physical force measurement and digital data analysis. These SOP load cell transmitter convert minute electrical signals produced by load cells that sense weight or force into readable and actionable information that helps streamline processes in industries to improve productivity while ensuring accuracy remains uncompromised. As technology advances further development of loadcell transmitters will enhance integration; this means they can be used to monitor control as well as optimize performance within different industrial operations.

The future of industrial weighing looks bright with new developments in load cell transmitters expected soonest; such devices will utilize cutting-edge technologies like IoT, AI among others besides adopting more enhanced connectivity protocols. Such SOP load cell shall allow for instant data transfer enabling businesses respond quickly to changes, forecast maintenance requirements and prevent downtimes. Also, upcoming designs intend saving power but without compromising on their ability to work efficiently thus making them fit better into highly compacted setups where space is limited yet complexity keeps on increasing day by day; therefore creating dynamic sustainable scales that are in line with fourth industry revolution principles.

Remote monitoring has been made possible through wireless enabled advanced models of these gadgets coupled with cloud compatibility features which have simplified everything about offsite supervision. Operators are now able to oversee processes from any location at any given time through continuous transmission of load data wirelessly to servers located away from the site or even control rooms within vicinity using this kind SOP weigh cells they need not be physically present there themselves. This innovation becomes very essential especially when dealing hazardous environments having minimum human presence or large scale operations distributed over wide geographical area thus requiring many points for measurement simultaneously With complex encryption algorithms employed during configuration phase together with robust integrity checking mechanisms put place while transferring over network security worries among people working around those places where these machines have been installed is completely addressed because it ensures data received was not tampered with before reaching destination. This allows industries to make quick decisions based on accurate updated information thereby optimizing utilization of resources while improving safety at work.

If you want to optimize efficiency, then load cell transmitters should be part of your process control system as they offer timely and precise weight readings. For instance in manufacturing sector batch production becomes more accurate hence lowering wastage level besides ensuring uniformity output throughout the entire process chain. In logistics industry it enhances better distribution cargoes which leads into efficient loading or offloading activities at various points so that vehicles do not carry excess weight beyond what their capacities can handle thus reducing wear tear on roads among other things. Apart from that by integrating these two SOP a load cell together one is able automate response basing on weights supplied triggering alarms adjusting speeds feeds changing parameters involved during different stages involved thereby cutting down manual interventions leading towards overall improvement in productivity levels achieved within given enterprise setting.

Load cell transmitters operating under tough conditions require robustness if they are to function effectively within harsh industrial environments where such measurements are necessary. SOP pressure sensor should be made resistant against moisture vibrations electromagnetic interference also capable of withstanding extremely high or low temperatures without affecting their accuracy margins which may vary depending on what kind metal used during construction materials science like corrosion resistant alloys plus advanced sealing methods help achieve durability longevity protection even when exposed harmful elements; moreover self checking features enable continuous monitoring for faults early detection further promoting strategies aimed at predictive maintenance ensuring reliability tools used keeping up quality standards across various sectors.

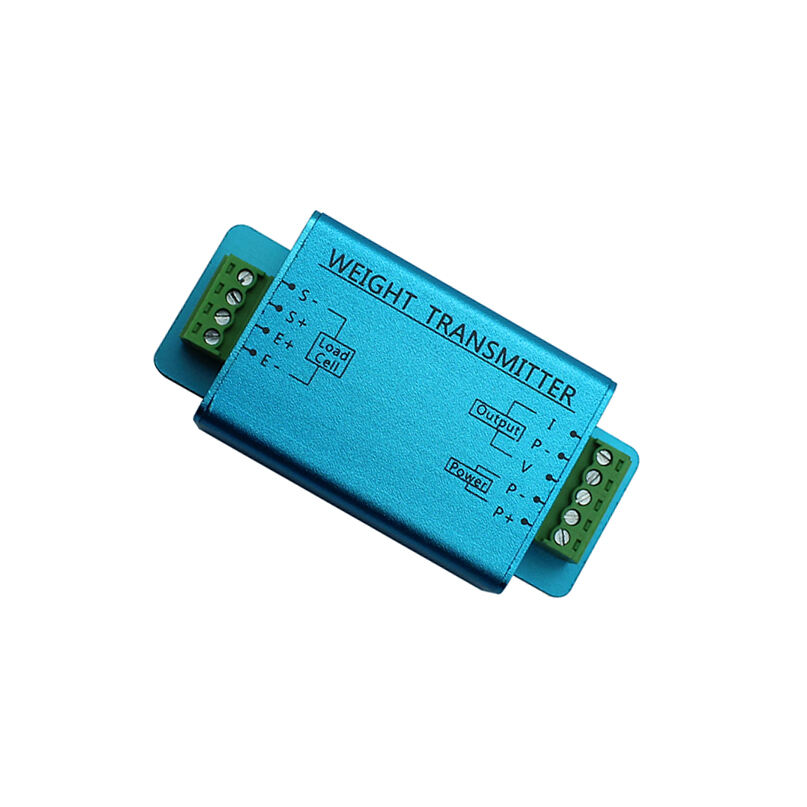

Our main products are comprised different types of sensors, such Load cell transmitter displacement sensor drawing wire sensor LVDT sensor, load cell torsion sensor, magneto sensor, pressure sensor, etc. We provide OEM/ODM services depending on the need's client.

We offer safe and secure packaging every item expedited shipping, with 2 days delivery for stock Load cell transmitter There several kinds shipping services for customer to select. Following the delivery you will be provided with the tracking information.

Our company certified by CE, RoHS, ISO9001 as well other certifications. Our products undergo rigorous testing prior delivery. SOP also offers engineers offer after-sales services Load cell transmitter any product issues.

SOP is a leading Load cell transmitter has over 20 years' manufacturing experience has worked with over 500 clients around world. SOP is a reputable firm is involved in the development, research production of various kinds of sensors.