Today, you can see pressure sensors being utilized everywhere from different industries as they are the correct devices to precisely measure pressure. Regular fine-tuning of these sensors is important to acquire accurate readings. Calibration is the process of comparing sensor output to a known pressure source, usually performed in a controlled laboratory environment using equipment such as dead weight testers or pressure comparators. Zeroing, Span adjustment and linearity testing (in a process called Z, S and L) ensure that these SOP Pressure sensor are accurate, repeatable and can be relied upon for long-term stability.

The pressure sensors, differential pressure sensors in particular, are capable in sensing the difference of airflow between two points. The SOP Pressure sensor can also measure the smallest pressure differentials with high accuracy, give you real-time ability and provide reliable readings everywhere. Precision and consistency are required in items such as HVAC systems, automotive engines or medical devices to name just a few applications where these sensors are used.

There are several key things to consider when choosing a pressure sensor for some great injury. Factors such as the pressure range to be measured, type of pressure being monitored (gauge, absolute or differential), accuracy levels required and output signal type should come into consideration. It is vital to make sure the measuring range of your SOP Pressure transmitter and signal conditioning system are matched against the requirements dictated by a particular application for highest performance.

Pressure sensors are composed of a number different technologies, with each having its own set of trade-offs. The method to measure pressure is different in strain gauge, capacitive, piezoelectric or resonant sensors and many more but they are the technologies. Strain gauges, although providing reliable measurements at a higher price point, are not as sensitive or precise when compared to capacitive sensors. A type of sensor called piezoelectric sensors could give you a quick and strong response and resonant sensors can provide high accuracy in frequency polarization measurement.

Customers Pressure transducer sensor from variety of transport options. We provide safe packaging speedy delivery all our stock items. You will receive tracking details following the delivery your goods.

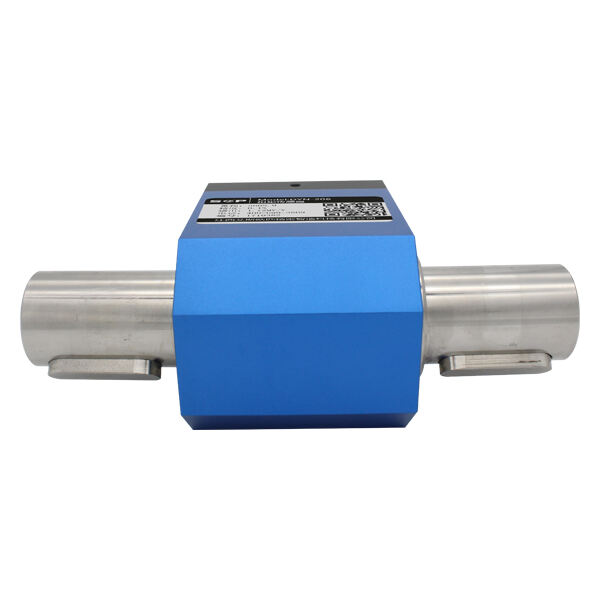

We provide a broad range products, including linear Pressure transducer sensor sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.

Our company accredited through CE, RoHS, ISO9001 as well other certifications. Before shipment, we examine each product. Additionally, SOP has professional engineers after-sales assistance to resolve Pressure transducer sensor and other issues.

SOP is a manufacturer high-tech Pressure transducer sensor that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.